3D printing is a rapidly emerging field at the moment. Its use requires mastery of the techniques and technologies related to it. It is therefore necessary to assimilate the concepts that concern them. It is also necessary to know the advantages that they bring to the user.

The Benefits of Using 3D Printing

From a technical point of view, the use of 3D printing brings many advantages to its beneficiary. First of all, the speed of production thanks to an exceptional execution speed. Indeed, it only takes a few hours to produce complex models. This allows users to reduce their manufacturing times. It will also allow errors to be quickly modified by effective verification of details. After that, this three-dimensional synthesis will reduce the cost of production. Indeed, the raw materials used in additive manufacturing are cheaper than those of traditional manufacturing.

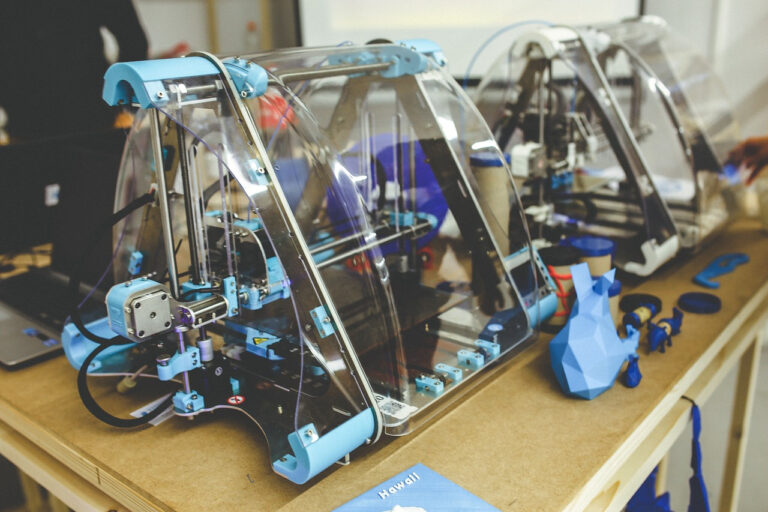

Various advantages are also associated with 3D printer technologies. First of all, this device is very convenient for making any object with very high precision. Whether it is children’s toys, dishes, or prototypes of factory parts. In addition to this, this machine will repair broken objects by producing spare parts. Its acquisition has become very simple. To have a high-performance printer, you just need to order from a specialized company.

The concepts of techniques and technology in 3D printing

The techniques group together the relative processes to find a 3D printing solution. They are numerous and can be very complex. First, is stereolithography, which consists of polymerizing liquid plastic using the heat of a laser. It allows the production of a solid and translucent object. Then, sintering consists of building 3D parts by heating fine particles. It is an additive manufacturing technique to synthesize plastic objects with four-color printing. There is also the material extrusion technique. This is based on the melting and extraction of materials through a nozzle. The molten material is thus deposited layer by layer for the synthesis of the object to be produced. Finally, laser fusions, which are prototyping and production processes. These operations are carried out for an assembly inside a powder bed. They allow the creation of metal prototypes with a change of alloy at each stage of this construction.

To achieve printing, the use of a 3D printer is required. It is a device connected to a computer that will produce a real object by modeling a drawn file. To be able to manipulate this device, it is necessary to install programs on the computer terminal. The CAD software will allow the modeling of the part. And the cutting software that will process it to obtain slices. Production also requires the use of cutting-edge technology. Indeed, these are high-tech components that make it possible to operate the printer. It will create any object, whether for mass production or prototyping. The size of this part depends on that of the printer. It is therefore possible to have large objects with a substantial manufacturing device.